With an ever-evolving environment, the journey into space is one fueled by innovation. Additive Manufacturing has been a game-changing adoption for the industry, allowing for more efficient allocation of weight on payloads, better part optimisation and expedited lead times.

After years of experience working side-by-side with industry-leading satellite and spacecraft manufacturers, we have built our service around quality, partnership, and collaboration. With globally recognized quality systems in place and validated processes ready, Zenith Tecnica is prepared to help global space companies reach the stars.

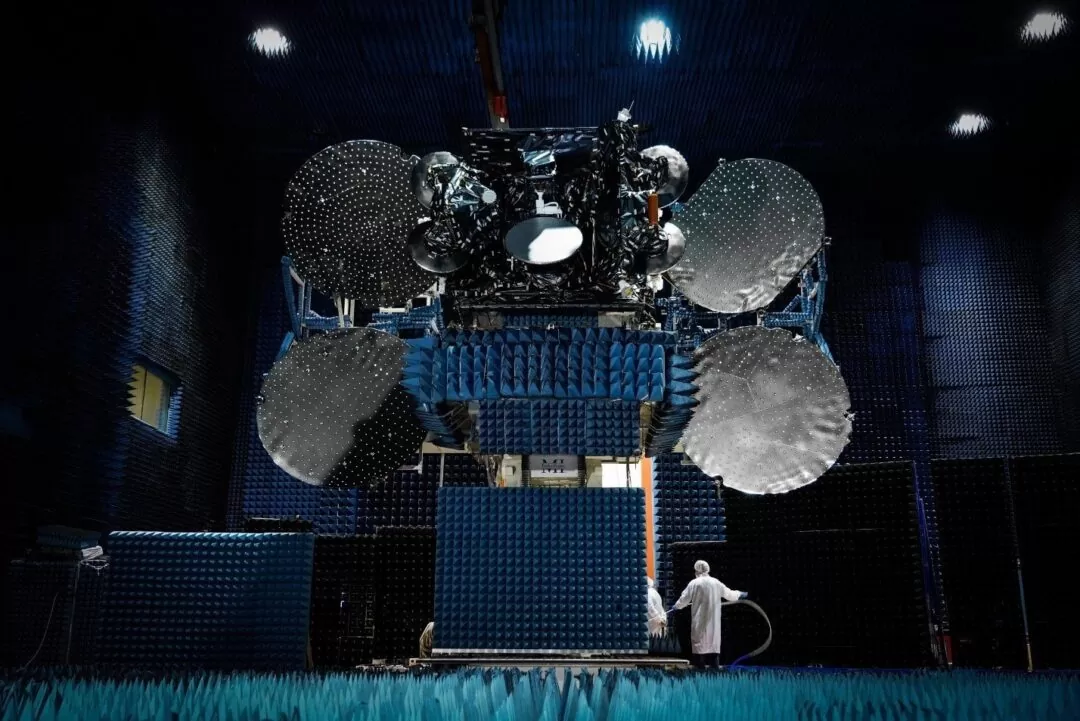

Since 2016, Maxar has built and launched five spacecraft with 260 titanium components produced by Zenith Tecnica using EBM additive manufacturing (AM) processes. More than 270 additional parts are currently in production and assembly on eight other satellites.

Since the introduction of AM into the production of spacecraft components, Maxar has achieved many benefits, including improved schedule agility, reduced manufacturing costs, and increased performance of satellites. Read more about our partnership here

Sending a large spacecraft, the size of a small bus, into the upper atmosphere takes an incredible amount of force. This force, alongside the harsh environment of space, where one moment you may be in the blistering heat of the sun to the next facing a freezing vacuum, requires the production of materials that will last. With the ever-growing need for efficiency in areas such as on-orbit-life, satellite manufacturers are moving to advanced manufacturing methods such as additive. In order to reduce mass, many structural designs have become more complex and organic in shape, which is only feasible through AM and the design optimization available.

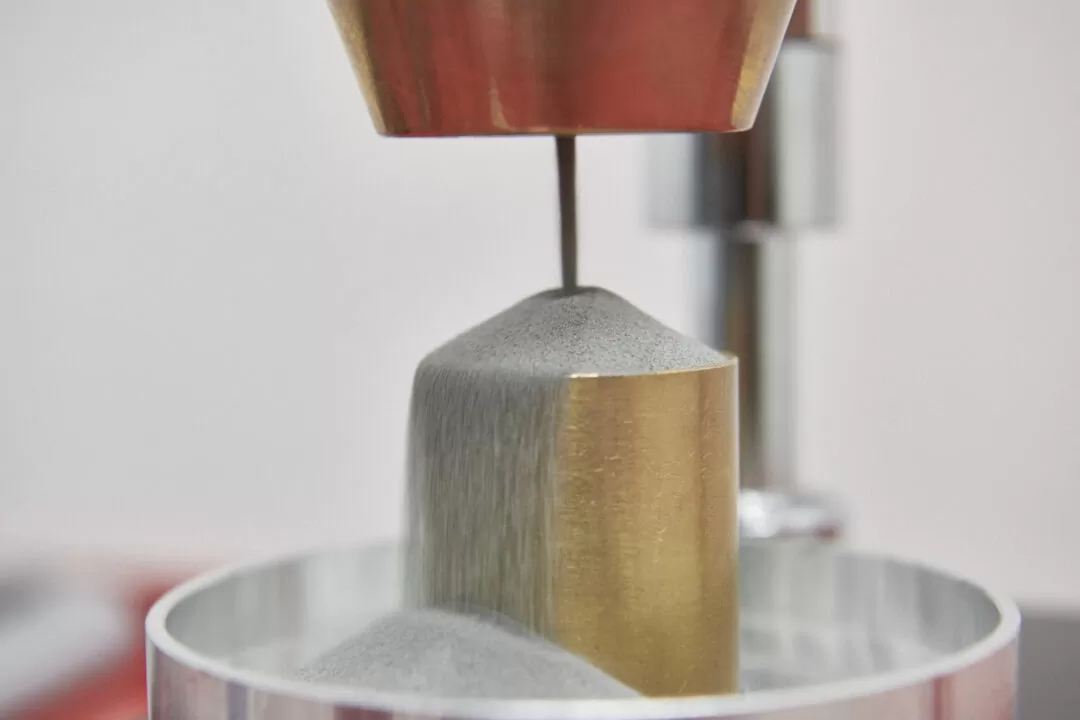

Our titanium EBM service allows for greater geometry freedom even over alternative metal AM methods. So you are able to build tall & thin-walled components, components with abrupt changes in thickness and lightweight structures that are optimized for mechanical and thermal loading.

Utilizing AM allows for benefits beyond the components themselves. From a supply chain standpoint, AM offers reduced tooling and with it, a shorter supply chain and ordering operation. With little set up requirements, customers can order exact quantities needed at cost-effective rates, to optimize spend and inventory.

Transition smoothly and efficiently from concept and prototype to production of qualified parts. Whether you require a primary supplier of titanium additively manufacturer parts or an overflow capacity supplier to meet crunch times, we are here for your needs.

Our team can collaborate with you to define a quality plan and validate a process to meet your project, monthly, quarterly, or annual requirements.