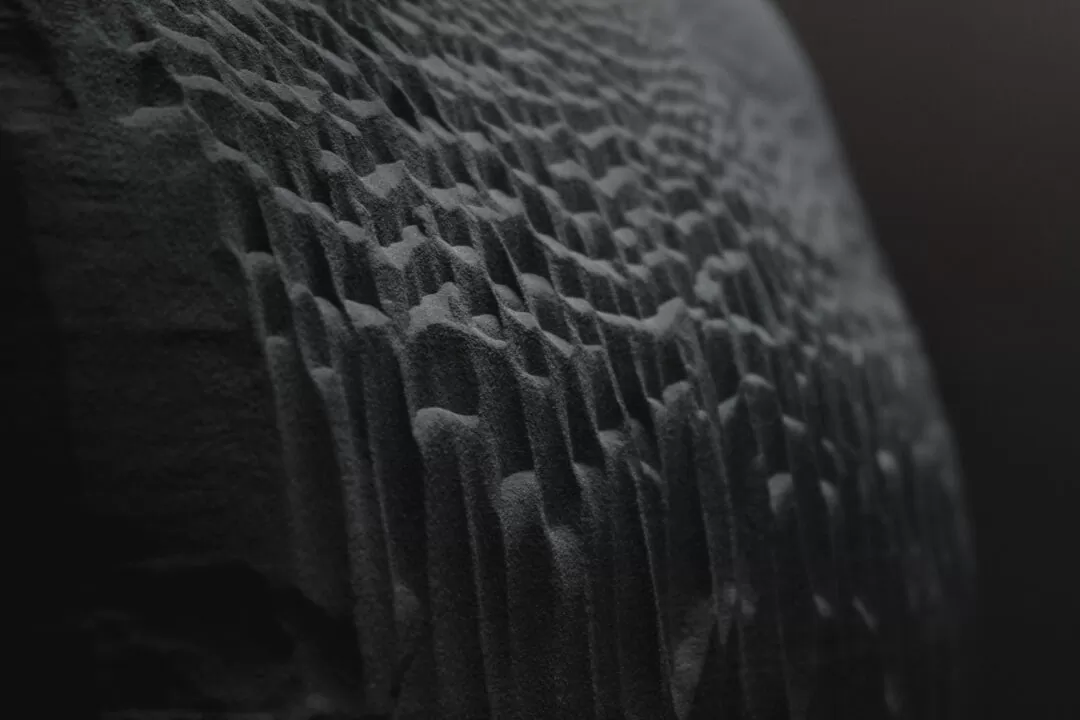

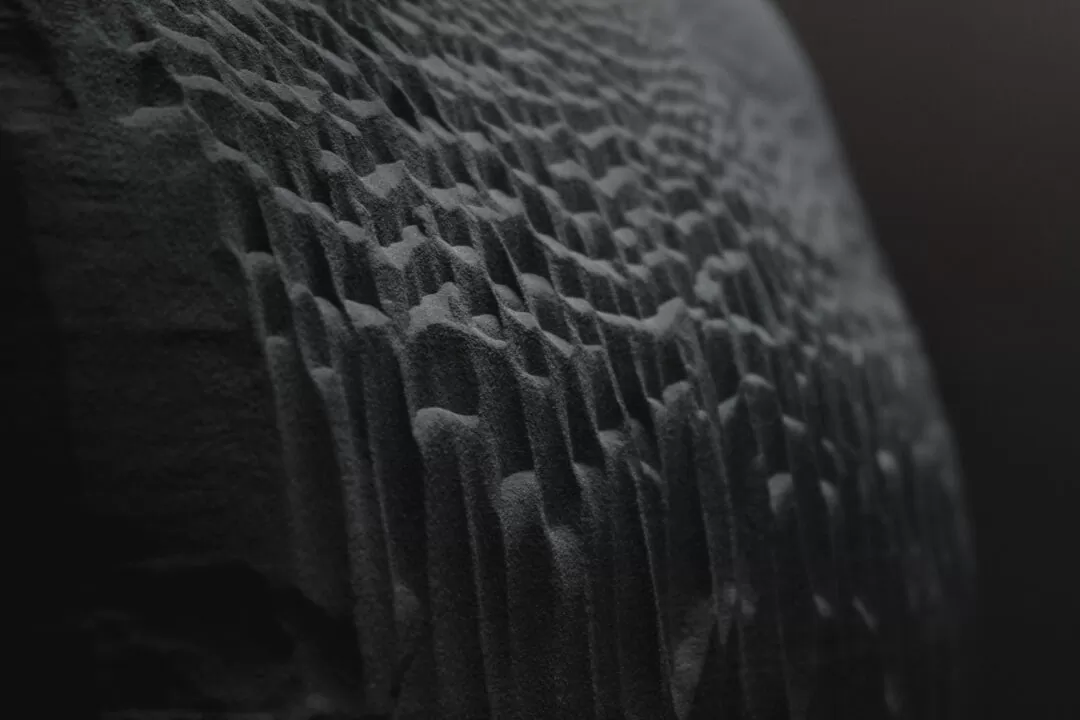

Zenith Tecnica was created with technology in mind and creativity at heart. Starting in 2014 with the goal to make titanium accessible through additive manufacturing, we have now grown and developed into world specialists in EBM.

Located in New Zealand, we have worked alongside and partnered with organizations and industry leaders from across the globe. We have created structural components on satellites orbiting above you right now, life-changing medical implants and even high-performance parts for sports syndicates such as America’s Cup Racing and Formula1 teams.

We utilize a fleet of GE Arcam Electron Beam Melting (EBM) machines. With a build volume of up to ⌀360x365mm and multiple machines at our fingertips – we have some of the largest EBM capacity in the southern hemisphere.

Through precise use of material, less waste and reduced need for tooling and labour during production – additive manufacturing is already an inherently sustainable option.

However, when merged with titanium, we create products that have greatly extended-life-cycles, through corrosion resistance and the structural capabilities offered.

Zenith Tecnica also participates in eco-friendly and socially sustainable practices, such as solar powered production, eco-friendly packaging, metal powder recovery & recycling, and university program sponsorship. This assists us in offsetting our freight emissions, as well as allows us to support the next generation of minds.

Operating in some of the worlds heaviest regulated industries means we have to stay on the top of our game every step of the way.

By meeting these international standards, we ensure all of our customers can have confidence in the products we develop together, and complete trust in our qualified and trained engineers. Our aim is to continuously be building on and growing with our current certifications and performance of our Quality Management System (QMS).

AS9100

Internationally recognized quality management standards for the aerospace industry.

Click here to view our certification.

ISO13485

Internationally recognized quality management standards for the medical industry.

A true testament to our commitment to Quality, Performance and our ‘Customer First’ attitude lies in the Qualification, IQ/OQ/PQ and calibration of all critical machinery involved in the production process.

Going above and beyond our Certification Marks, all in the name of quality production.

Zenith Tecnica is committed to compliance with all import/export regulatory controls such as the U.S. International Traffic in Arms Regulations (ITAR) and U.S. Export Administration Regulations (EAR).

Our team works diligently with our international customer base to ensure compliance with each country’s import and export requirements.

Traceability at Zenith Tecnica is built into all of our processes.

All our raw materials can be traced to their source of origin, and can be followed at each step of the production process.

Furthermore, we operate with tight controls of our production means, from parameters to testing, ensuring conformance of your parts with ASTM material standards and manufacturing good practice.

Our team is our greatest asset.

The way we collaborate, support and respect each other is how we maintain such a high level of work. These ideas and values shape our identity, drive our decisions and impact the mark we leave on the world.

In short, we just want to make the best parts we can, enjoy what we do and bring the best service to our customers as possible.

MISSION

STATEMENT

We use transformative technologies and personalized solutions to produce incredible products.

VISION

STATEMENT

Inspiring the world to reimagine manufacturing.

Working with each other, our customers, stakeholders and the wider community for the best possible outcome.

We know there are always different and possibly better ways of doing things – and it is our job to find them.

Quality is more than a tick-box. We strive to do the best in everything we do. Not just within the parts we produce but the service we provide, the conversations we hold and the work we carry out.

Our lives, aspirations, families and loved ones make us who we are. To succeed, we must support ourselves and those around us.

We are always looking for the next bright mind to join our team. If you are passionate about what you, we want to hear from you!

Heather is the founder of the TechBiz Success Academy, and Success With Grace Ltd, an NZTE registered training provider specialised in growing successful technology businesses.

Heather has over 30 years’ commercial experience in the science, engineering and technology sectors. She was co-founder of Technology Systems and held Sales Management, Business Development, Network Management and General Management roles with Bayer NZ, Downer EDI and Rebain International.

Heather holds an NZCS in Chemistry, an NZIM Management Diploma and a Diploma in Workplace Psychology. Her background provides Zenith Tecnica with expertise in sales and business growth strategies, leadership and talent management. She also brings international business experience in technology, manufacturing, service, distribution and supply chain management.

In her spare time, Heather enjoys ocean swimming, scuba diving and sailing.

New Zealand Certificate in Boat Building

Certificate of Completion in U.S Export Controls Training – World Trade Center Denver

Dan has been the workshop manager at Zenith Tecnica since 2016. He has picked up new skills working with Arcam EBM machines and enjoys the challenges that come with them.

Dan is a very hands-on person with 16 years in light to heavy welding and fabrication. During this time he spent a large portion of time building and installing large machinery around the world which included working with hydraulics and electrical systems.

Outside of work Dan spends weeks volunteering his skills to fix DOC huts and tracks in the south island. He enjoys the outdoors; boating, fishing, tramping, hunting and staying fit.

Bachelor of Engineering (Hons) Biomedical – Dublin City University

Scott joins Zenith Tecnica as our new Mechanical Engineer. Originally from Ireland, he holds a Bachelor of Engineering (Honors) in Biomedical Engineering from Dublin City University.

He brings a wealth of engineering expertise, having served in various roles including Service Engineer, Field Service Team Leader and Design Engineer. Having made the leap to New Zealand just over a year ago, he’s bringing yet another international perspective to our innovative team.

With years of CAD experience, Scott’s passion for additive manufacturing has been a driving force ranging from academic to personal projects. Whether designing solutions for complex challenges or bringing creative concepts to life in his personal projects, Scott’s versatility and ingenuity shine through.

Throughout his career he has honed his customer facing engineering skills. His previous leadership experience adds a valuable dimension to our collaborative environment.

Beyond the tech realm, Scott is a football enthusiast, embracing outdoor activities and fueled by a love for creative learning. He is captivated by space, nature, the intricacies of the human body and how things operate.

Bachelor of Business – Massey University

Fundamentals of Digital Marketing Certificate – Google Digital Garage

Morgan started with Zenith Tecnica in early 2021 as Digital Marketing & Customer Service Coordinator, taking on the task of working with the team to create a new and comprehensive marketing strategy to fit with the growing nature of the business. After completing his Bachelor of Business, Morgan has worked in marketing and project management roles for multiple technical industries and has found a passion in strategy and implementing sustainable practices.

He has always had an interest in the creative design process from start to finish, even beginning his time at university studying architecture. As such, Zenith Tecnica was the perfect meld of technicality, design and creativity. Morgan now heads up the marketing department as Marketing Manager.

In his spare time, Morgan is an avid photographer and loves finding new and interesting compositions and combining his creative and technological side with photo manipulation and editing.

Bachelor of Engineering (Hons) – Mechatronics, The University of AucklanD

GE Additive – Arcam EBM Material Development (Level 3)

Hi-Tech Metrology – Geometric Dimensioning and Tolerancing with Coordinate Metrology

Applied Vehicle Dynamics Seminar, Optimum G

Certificate of Completion in U.S Export Controls Training – World Trade Center Denver

Peter leads Zenith Tecnica’s customer engagements and the engineering team to ensure that customer requirements are met. Peter started with Zenith Tecnica as a mechanical engineer in 2016 and has been a leader in the production team since 2018 when he was managing day-to-day production efforts. Since then he has moved to further engaging with customers to help solve their technical challenges and meet their ever-changing production requirements as demand for our services has grown.

Because Peter has been part of every stage of Zenith Tecnica’ s manufacturing processes since 2016 he has a wealth of knowledge to share with our customers to help them take their products to market.

Prior to starting at Zenith Tecnica, Peter spent time at Fisher and Paykel Healthcare in 2015 working on accelerated life testing, gauge repeatability and reproducibility, and various other metrology areas in an ISO13485 medical device production environment.

While at the University of Auckland, Peter was the team manager of the Formula SAE Team – A team of 50 that designs, manufactures, and races a formula style open-wheel race every year. After leading the development to an electric powertrain, he has good understanding of mechanical and electrical systems, maintaining relationships with sponsors & suppliers, and the challenges of running a technical team. Peter was also involved in the composites team and has experience in mould making, hand laying pre-impregnated fibres, wet laminating, and infusing CFRP components.

In his spare time, he enjoys road trips, swimming, and spectating or participating in motorsport events.

Arcam EBM Certification Training Level 1

Certificate of Completion in U.S Export Controls Training – World Trade Center Denver

Emil first joined Zenith Tecnica in 2016 after obtaining Level 1 EBM certification in his home country and the home of GE Additive Arcam, Sweden, before coming to New Zealand for a year of work experience. Emil came back on board in 2019 as our workshop assistant after moving back to New Zealand. Emil also serves as our health and safety officer.

Emil has worked in a variety of roles such as lamination – hand laying fiberglass, warehouse and recycling operation, as a food courier, and even as an operator in an ice cream factory!

Emil is a lover of everything outdoors and enjoys playing music, hiking and camping, gardening and DIY, surfing, swimming, running, and woodworking!

Previously, Zenith Tecnica had the pleasure to work with Philipp as a PhD student while he completed his thesis on ‘Additively Manufactured Titanium Alloy Sandwich Structures for Thermal Protection’. He has since presented parts of his research at the European Conference for Aerospace Sciences (EUCASS) in Switzerland.

We are thrilled as he is now a part of our engineering department full-time, bringing a wealth of knowledge in aerospace and material science.

Emma joined Zenith Tecnica in July of 2021, as the Administration Assistant and quickly rose to the task of becoming our export compliance officer, and has since moved into the quality team and is heavily involved in the Quality Management System and Logistics.

Emma has a working background in various industries including utilities & hospitality. She has a keen interest in problem solving and streamlining processes.

In her spare time, Emma enjoys roller skating, music, macramé and gaming.

Will joined Zenith Tecnica as General Manager in September of 2022.

Joining the team with a background as Chief Scientific Officer, Will is an accomplished and proven executive with a strong technical background, strategic planning, and commercial acumen. With years of extensive experience managing research and development, product innovation, regulatory and quality affairs, and IP development, Will is positioned to take Zenith’s growth to the next level.

Prior to starting at Zenith Tecnica, Will’s career has been in the life sciences, most recently as CSO and Medical & Scientific Affairs Director for MitoQ Ltd where he oversaw the consumer healthcare business’s scientific and technical departments. He has also held managerial positions within the STEM publishing and health informatics sectors.

Outside of work Will enjoys playing piano, gardening/landscaping, keeping fit and spending time with his young family.

Certificate of Completion in U.S Export Controls Training – World Trade Center Denver

Mo comes to us from an extensive and highly qualified background in Quality, Health and Safety and technical expertise and is ready to jump into our existing Quality Management System.

Leading the charge to ensure we remain at the top of our game. With our current quality standards in place and others on the horizon, it is no small task to take on!

Logan joined the Zenith Tecnica team in April 2021, moving up to to Auckland from Blenheim in the process. Logan Completed his Mechatronics Engineering degree at Massey University in 2020 and always had a keen interest in additive manufacturing.

He initially started at Zenith in the workshop team, learning the in’s and out’s of the EBM machines and understanding the production process. He then moved into an engineering role within the production team working on nesting, supporting and quoting.

Logan has since stepped into the Production Manager position where he leads the team of engineers, manages customer and supplier relationships and oversees and ensures the smooth building and delivery of components to our customers.

In his spare time, he enjoys cars, 3D printing and extra long walks on the beach.

Auto CAD Fundamentals

Certificate of Completion in U.S Export Controls Training – World Trade Center Denver

Callan joined the Zenith Tecnica production team in 2022 as Workshop Engineering Assistant. Outside of work, his hobbies involve all things DIY. Including brewing beer and distilling spirits, gardening, graphic design, building and mechanics. As a creative yet logical thinker, he thrives

while exploring functionality and efficiency in processes. He is mechanically minded and enjoys reverse engineering objects to understand how they operate.

Outside of work he spends a lot of time outdoors, swimming, tramping, diving and holds a PADI Diving license.

Certificate of Completion in U.S Export Controls Training – World Trade Center Denver

Tracy started with Zenith June 2023 as the Office and Accounts Manager, coming from an 18-year stint in the Chemical Industry as a Financial Administrator and managing most of the office tasks, leading her to the role with Zenith.

Her interests involve actively playing badminton, North Harbour Badminton Master’s Rep and running a club weekly at North Harbour, loves watching all Motorsport, mostly off-roading or 4x4ing.

Bachelor of Engineering (Hons) – Mechanical, University of Canterbury

Certificate of Completion in U.S Export Controls Training – World Trade Center Denver

Luke started at Zenith Tecnica in March of 2021, as a Mechanical Engineer and has become an extremely valuable asset to the team. He excels in leading projects and helped take the team to new heights when he took on the Production Manager role.

After graduating from the University of Canterbury in 2017 with a Bachelor of Engineering (Hons), Luke has had experience in several engineering design and project engineering roles. This gave him exciting exposure to a range of projects and has allowed him to bring extensive knowledge and different insights to Zenith Tecnica. He has also had plenty of time on the tools in manufacturing plants doing maintenance and repair work. Luke excels with problem solving, and is a valuable member of the team.

Outside of work, Luke enjoys everything surfing and skating related and is always looking for new coastlines to explore.

BTEC Higher National Diploma – Advanced Diploma in conception & industrialisation of Microtechnology, Noisiel – France

Certified Auditor (ISO9001, ISO13485)

Certificate of ISO Management System Audit Techniques and Best Practices Certified Internal Auditor

SOLIDWORKS (BASW1 & Advanced Drawing)

Certificate of Completion in U.S Export Controls Training – World Trade Center Denver

Victor joined Zenith Tecnica with his background in quality systems after a push for AS9100:RevD and future certifications. He began his career 10 years ago completing contract work for a design office and workshop creating 3D models and prototypes. Following this he worked for a Medical Device company in Paris for 7 years and participated in the development and design of 16 new surgical instruments that were FDA-approved and CE marked. This included design transfer, risk analysis, implementation of product change management tools, defective product analysis and more.

Victor left France in 2016 and began working for a sapphire mining company in Mauritius as a quality manager contractor where he created a traceability system and certification process for ethical sapphires to guarantee ‘mine to market’ traceability. This involved integration of quality management systems, project management, training, implementation of quality tools and marketing team support.

Upon arriving in New Zealand in 2017 he took a position as a program manager and auditor for the medical branch of a Conformity Assessment Body (CAB) before moving to Zenith Tecnica.

Outside of work Victor enjoys exercising, running and exploring New Zealand!